Unistrut Curved Track / Trolley Track Applications & Advantages

Unistrut systems have long been the foundation for innovative metal framing solutions, offering versatility across multiple industries. Among these systems, the Unistrut curved track stands out as a critical component for complex designs and infrastructure projects that require flexibility beyond traditional, straight strut channel. Whether for architectural projects or industrial applications, curved Unistrut tracks provide reliable solutions that meet modern engineering demands.

In today’s world, complex framing configurations often require adaptable solutions to overcome design challenges. The flexibility of curved tracks allows architects, engineers, and builders to implement creative designs without compromising strength and durability.

The Importance of Curved Unistrut Track

As construction and design evolve, the need for adaptable solutions has grown. Traditional straight tracks can limit design possibilities, particularly in projects with non-linear layouts or unique architectural structures. Curved Unistrut tracks provide the necessary flexibility to accommodate bends, corners, and arcs while maintaining the same strength and load-bearing capabilities as straight tracks.

Curved Unistrut tracks also offer greater efficiency in space utilization and a streamlined aesthetic for projects requiring a non-linear design. In spaces with curved walls or ceilings, for instance, these tracks integrate seamlessly, allowing for essential support systems without interrupting the flow of the design.

Applications of Curved Unistrut Track

Construction and Architecture

Curved Unistrut tracks are widely used in modern architectural designs, providing a solution for creating smooth, flowing spaces. These tracks are ideal for use in structures with curved ceilings, walls, or facades, enabling architects to realize their vision without sacrificing structural integrity. Curved tracks also facilitate the integration of essential systems, such as lighting and HVAC, along non-linear surfaces.

Industrial and Manufacturing

In industrial settings, curved Unistrut tracks are essential for supporting heavy equipment and machinery, especially in spaces with tight or irregular layouts. Assembly lines often benefit from these tracks, which allow for better equipment placement and improved workflow. By following the natural layout of the facility, curved tracks provide a flexible solution that enhances production efficiency.

Transportation Infrastructure

Transportation infrastructure projects, including tunnels and bridges, often require cable management and support systems that follow the curves of the structure. Curved Unistrut tracks offer an efficient solution, allowing essential systems such as electrical and communication cables to be securely managed along curved pathways. This improves the overall safety and organization of infrastructure projects.

Commercial and Retail Spaces

In commercial and retail environments, curved Unistrut tracks enable creative shelving and display designs that draw customer attention. Retailers use these tracks to create flexible layouts that can be adapted quickly for seasonal changes or new product lines. Curved tracks offer both functionality and a modern aesthetic, enhancing the overall design of the space.

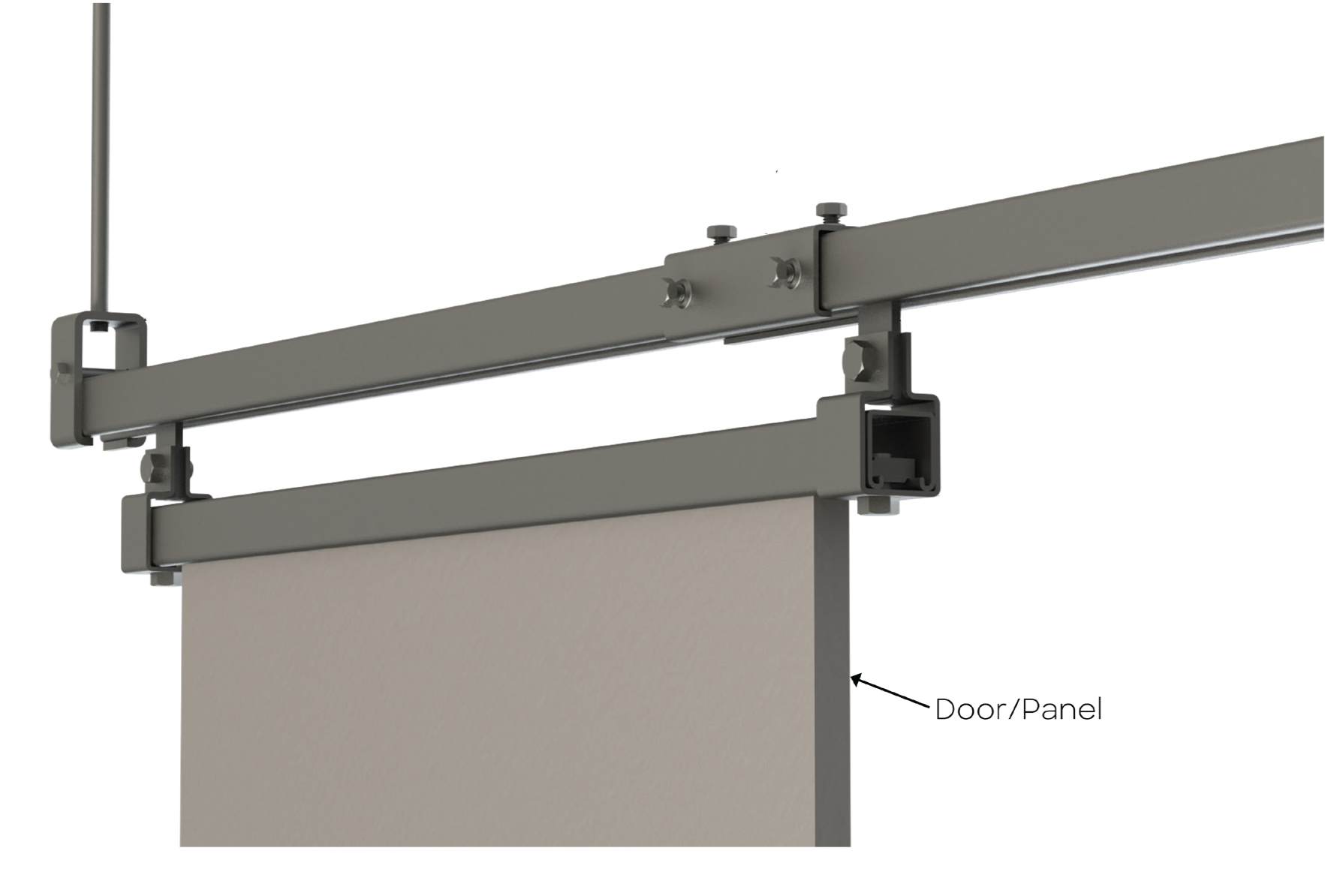

Unistrut Trolley Track Applications

Unistrut curved tracks paired with Unistrut trolleys offer an efficient solution for overhead mobility applications across various industries. One common use is in ceiling mounted patient lift systems in healthcare facilities. These systems rely on curved Unistrut tracks to navigate around rooms and hallways, allowing medical staff to safely transfer patients from beds to wheelchairs or treatment areas. The smooth, durable trolley mechanisms ensure consistent and reliable movement, improving patient safety and comfort while reducing strain on caregivers. The flexibility of the curved tracks enables these systems to be installed in irregular spaces, maximizing utility in often complex healthcare environments.

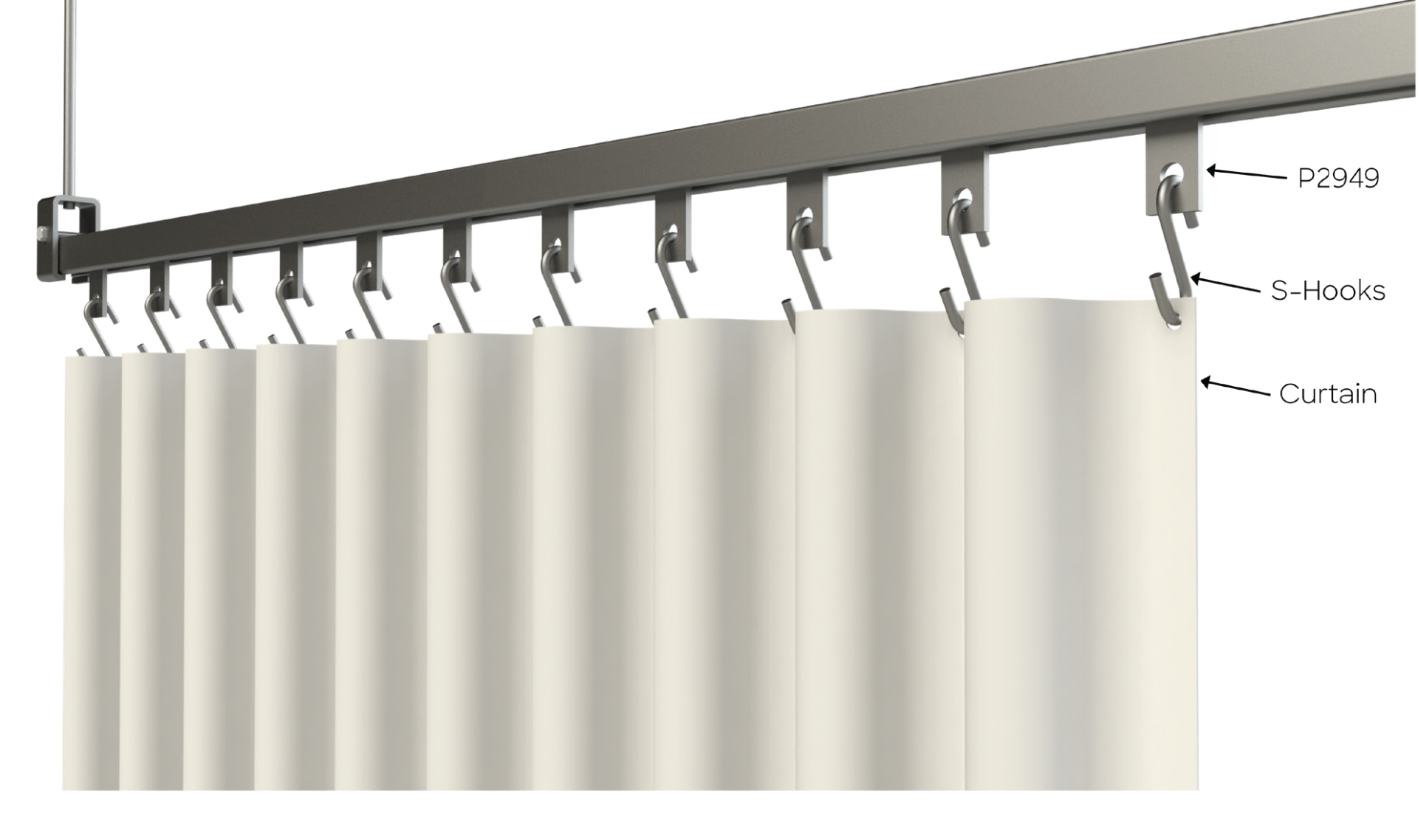

Another key application is in sliding curtains and walls, often seen in hospitals, industrial settings, and theaters. Curved Unistrut tracks are ideal for supporting these systems, as they allow for the smooth sliding of partitions around corners and along curved paths. This adaptability is particularly useful in spaces where straight tracks would limit design possibilities, such as when dividing large rooms or creating adaptable open spaces. Additionally, in industrial material transfer systems and welding curtains, Unistrut curved tracks combined with trolleys provide seamless overhead mobility, enabling safe and efficient movement of materials or protective barriers. Whether it's for rolling doors in warehouses or customized mobility solutions in commercial environments, Unistrut trolley systems enhance operational efficiency and safety.

|

|

Advantages of Using Curved Unistrut Tracks

Curved Unistrut tracks offer a variety of key benefits that make them invaluable in modern construction, industrial, and commercial projects. Their unique features—flexibility, durability, ease of installation, and versatility—translate into real-world solutions that help engineers, architects, and contractors achieve more efficient, aesthetically pleasing, and cost-effective designs.

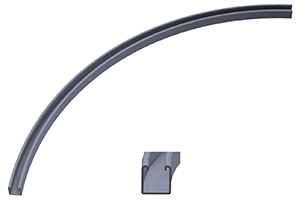

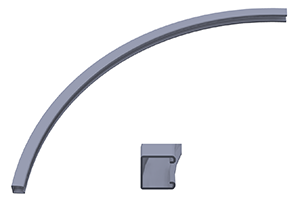

| Slot to Side | Slot In | Slot Out |

|

|

|

- Flexibility: One of the primary advantages of curved Unistrut tracks is their ability to accommodate non-linear pathways. Unlike traditional straight tracks, curved Unistrut tracks can be adapted to follow arcs, bends, and irregular layouts, making them ideal for projects where space constraints or design aesthetics require a more flexible approach. This flexibility is crucial in architectural designs with curved walls, ceilings, or facades, where a rigid track system would be impractical.

In real-world applications, the flexibility of curved Unistrut tracks allows for the seamless integration of structural supports, utility systems (such as HVAC and electrical wiring), and even aesthetic elements in environments where traditional systems would fall short. This adaptability also ensures that curved tracks can be used across a range of industries, from transportation infrastructure to retail environments. - Durability: Curved Unistrut tracks are constructed from high-quality materials designed to withstand harsh conditions and heavy loads. This durability ensures that the tracks can perform reliably in challenging environments, such as industrial facilities or outdoor infrastructure projects, where exposure to the elements or constant mechanical stress is a concern.

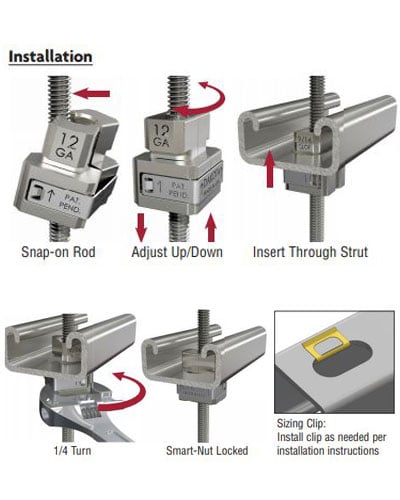

The durability of Unistrut systems means fewer maintenance requirements and a longer service life, making them a cost-effective solution for projects that demand longevity. Whether used to suspend heavy machinery in manufacturing plants or to manage essential systems in transportation tunnels, the robust nature of curved Unistrut tracks guarantees that they can endure even the toughest conditions. - Ease of Installation: One of the standout benefits of Unistrut systems, including curved tracks, is the ease of installation. The modular design of the tracks, combined with a wide range of fittings and accessories, means that these systems can be installed quickly and efficiently with minimal tools. This is particularly advantageous in projects with tight deadlines or complex layouts, where installation speed is a priority.

In practice, this ease of installation translates to reduced labor costs and minimized disruption to ongoing operations in commercial or industrial settings. Contractors appreciate the straightforward installation process, as it allows them to complete projects faster without compromising on quality or safety. The ability to quickly adapt the track layout to changing requirements also makes Unistrut systems an appealing choice for projects where modifications may be needed during or after the initial installation. - Versatility: Curved Unistrut tracks are known for their versatility. They can be used in a wide range of applications, from supporting electrical conduits and HVAC systems in commercial buildings to suspending heavy equipment in industrial environments. This versatility is due to the wide variety of compatible components and fittings that allow the tracks to be customized for almost any purpose.

⇔

In real-world applications, this means that Unistrut curved tracks can be tailored to fit the unique demands of each project, regardless of industry or environment. Whether used in the retail sector to create dynamic shelving displays or in transportation infrastructure to manage cables along curved tunnels, Unistrut tracks provide a flexible and reliable solution.

The versatility of Unistrut curved tracks makes them an indispensable tool across industries, offering solutions that address both aesthetic and practical needs. Their flexibility allows for seamless integration into complex designs, while their durability ensures long-lasting performance in challenging environments. Whether used to enhance architectural spaces, improve industrial workflows, or optimize infrastructure, Unistrut curved tracks offer a blend of functionality and adaptability that makes them an ideal choice for modern engineering challenges. With their ease of installation and broad range of applications, these tracks continue to set the standard for reliable, efficient framing and mobility systems.

⇔

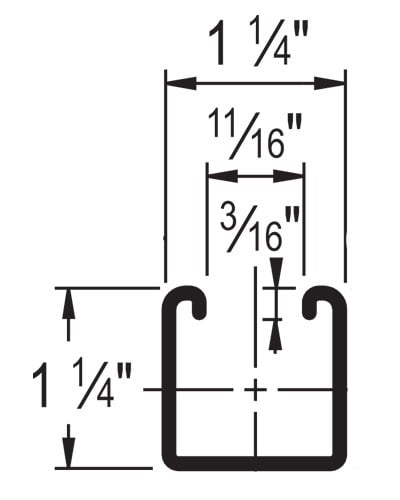

For more detailed information about what specific Unistrut Curved Track is available, including General Specifications, such as: Channel Profile Options, Materials & Finishes, as well as information about Channel Radius and Available Lengths, please visit our Unistrut Curved Track Page.

Ready to Order Now? Fill out our Unistrut Curved Track Quote Request Form