How Fiberglass Unistrut Minimizes Conductivity & Enhances Safety in Data Center Construction

Power Up Your Data Center's Safety: How Fiberglass Unistrut Minimizes Conductivity

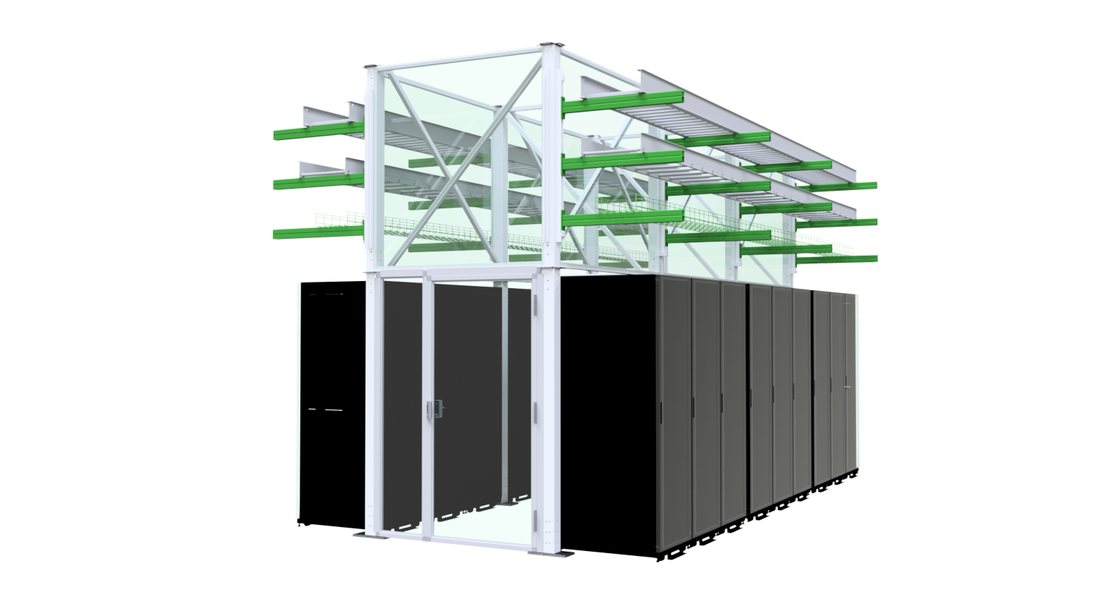

Data centers are the beating hearts of our digital world, humming with power and information. But with all that electrical activity comes a constant concern: safety. One way to ensure a safer environment is by limiting conductivity within the data center itself. This is where fiberglass unistrut comes in. Fiberglass is a non-conductive material, that along with improved safety, also provides several other key benefits.

Traditional Unistrut: A Workhorse, But With Limitations

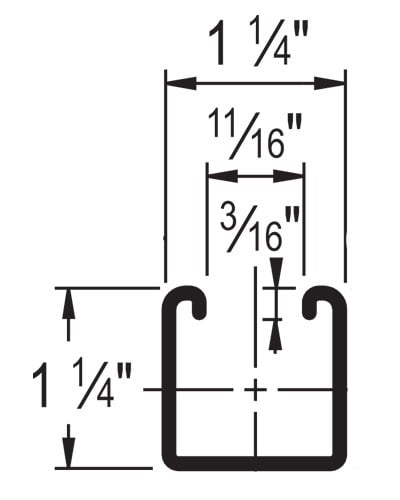

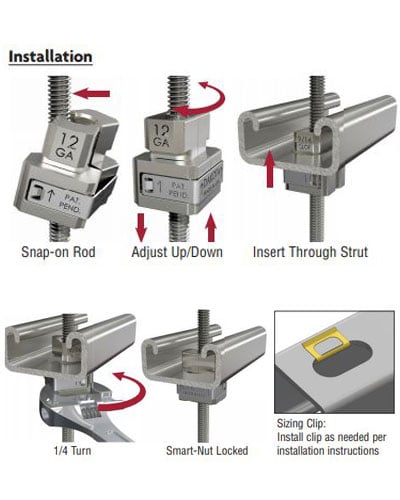

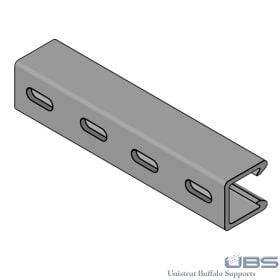

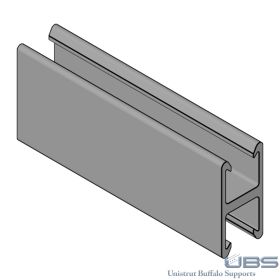

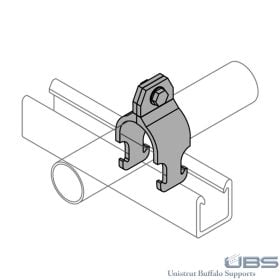

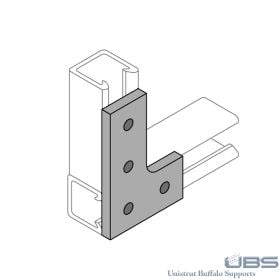

Many data centers rely on Unistrut, a versatile metal framing system, to support critical infrastructure like cable trays, conduit, and piping. However, traditional steel Unistrut conducts electricity. In the event of a fault or surge, this conductivity can pose a serious safety risk. With fiberglass Unistrut, this risk is no longer a factor. Fiberglass Unistrut products consist entirely of non-conductive material.

Fiberglass Unistrut: A Non-Conductive Champion

Fiberglass unistrut offers a compelling alternative. Made from non-metallic, corrosion-resistant resins, it provides all the benefits of traditional unistrut – strength, versatility, and ease of use – without the electrical conductivity. This makes it ideal for data centers seeking to:

- Enhance Electrical Safety: By minimizing potential current paths, fiberglass unistrut reduces the risk of electrical shock and equipment damage during accidental grounding or fault conditions.

- Protect Sensitive Equipment: Data center equipment is delicate and expensive. Fiberglass unistrut helps safeguard it from stray currents that could cause malfunctions or data loss.

- Comply with Regulations: Many data center regulations emphasize safety measures to prevent electrical hazards. Fiberglass unistrut can be a valuable tool for meeting these compliance requirements.

Beyond Safety: Additional Benefits of Fiberglass Unistrut

The advantages of fiberglass unistrut extend beyond electrical safety. Here are some other reasons to consider it for your data center:

- Corrosion Resistance: Unlike steel, fiberglass unistrut is impervious to rust and corrosion, even in harsh environments. This translates to a longer lifespan and lower maintenance costs.

- Lightweight Advantage: Fiberglass is significantly lighter than steel, making it easier to handle and install. This can be a major benefit in large-scale data center projects.

- Radio Frequency Transparency: Certain applications in data centers, like cellular deployments, require radio frequency transparency. Fiberglass unistrut won't interfere with these signals.

Making the Switch To Fiberglass Unistrut

Fiberglass unistrut is readily available from several manufacturers and comes in a variety of sizes and configurations to meet your specific data center needs. When considering a switch, consult with qualified professionals to ensure compatibility with your existing infrastructure and achieve optimal safety and performance.

By incorporating fiberglass unistrut into your data center's design, you're making a proactive investment in safety, efficiency, and long-term value. It's a smart move that keeps your data center – and your critical data – protected.

For more information on fiberglass Unistrut and dater center construction, visit our data center construction page. Looking for a system customized to your needs? Visit Modular Mechanical Systems and recieve a quote today!

Have a project and in need of guidance?

Let our experts assist you in making the right decision!

Give Us A Call Today +1 (800) 285-3056