Unistrut Defender

Longer Life at a Lower Cost

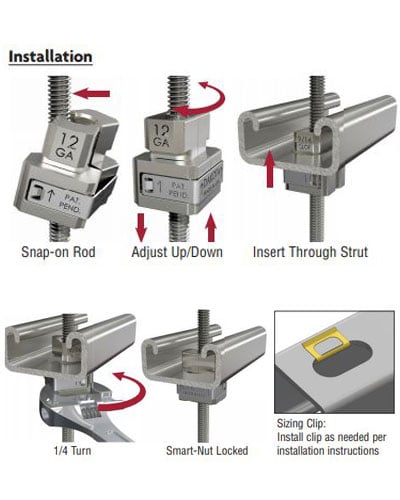

The best way to defend your investment is to select a product that is guaranteed to extend the service life of your building. The Atkore Defender premium finish ensures superior performance for years to come while reducing maintenance costs in the long run. So when building in harsh environments reach for the most complete metal framing system on the market today to defend against corrosion on your next project. Defender premium finish is designed to streamline your installation process.

When it comes to Atkore Defender premium finish, labor savings is something that you can count on. It's engineered right into the finish, so when you cut or scratch the coating it self-heals, eliminating the need for secondary touch-ups. Additionally, it makes it easier to thread coated fasteners and eliminates the binding of threads associated with Hot-Dip Galvanized.

For decades, engineers have had limited choices when it came to protecting steel from corrosion in outdoor environments. Hot dip galvanized (HDG) has long been the standard and provides a good level of protection, but most often will not protect the steel for the entire service life of the facility. Stainless steel has been another option to provide superior protection, but at a much higher installation cost.

Get Better Performance with Unistrut Defender

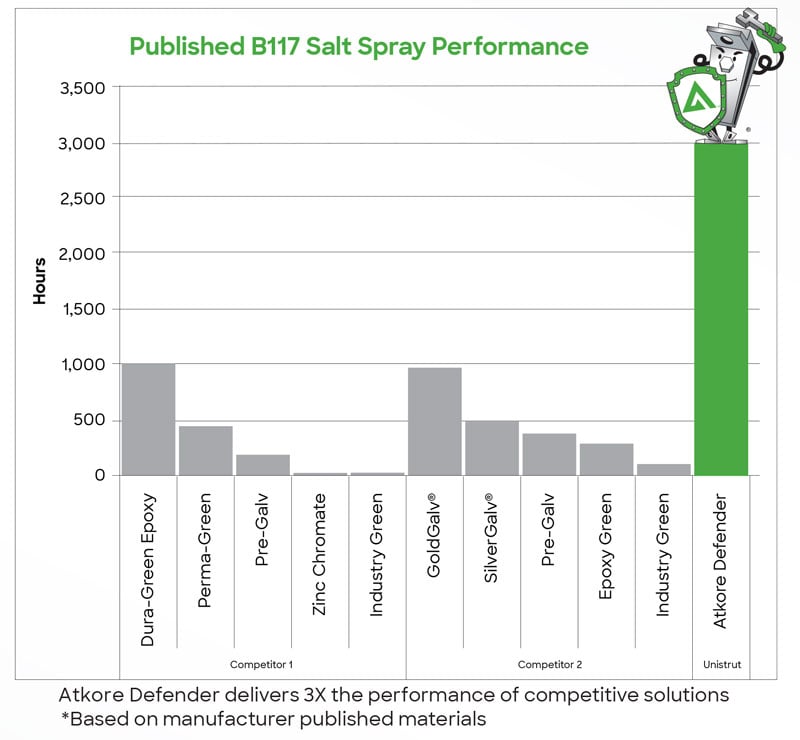

Atkore Defender is designed for harsh environments, providing a service life between Hot-Dip Galvanized and stainless steel systems. Independent testing shows that Atkore Defender is THREE times more corrosion-resistant than Hot-Dip Galvanized products. In addition, Atkore Defender avoids the use of costly stainless steel hardware.

Unistrut Defender is a great choice for harsh and corrosive environments.

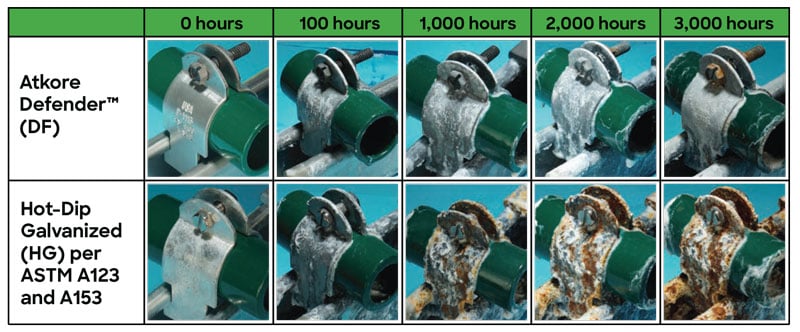

Corrosion Protection

Atkore's Unistrut Defender coating was tested against the traditional Hot-Dip Galvanized coating by an independent, accredited 3rd party laboratory for 3,000 hours of continuous salt spray exposure per ASTM B117. The test was conclusive, proving that Atkore Defender outperforms Hot-Dip Galvanizing by lasting 3 times as long before reaching the 5% red rust failure criteria!

The photos below show the clearly superior performance provided by Atkore Defender.

PHOTOS FROM ASTM B117 SALT SPRAY TEST

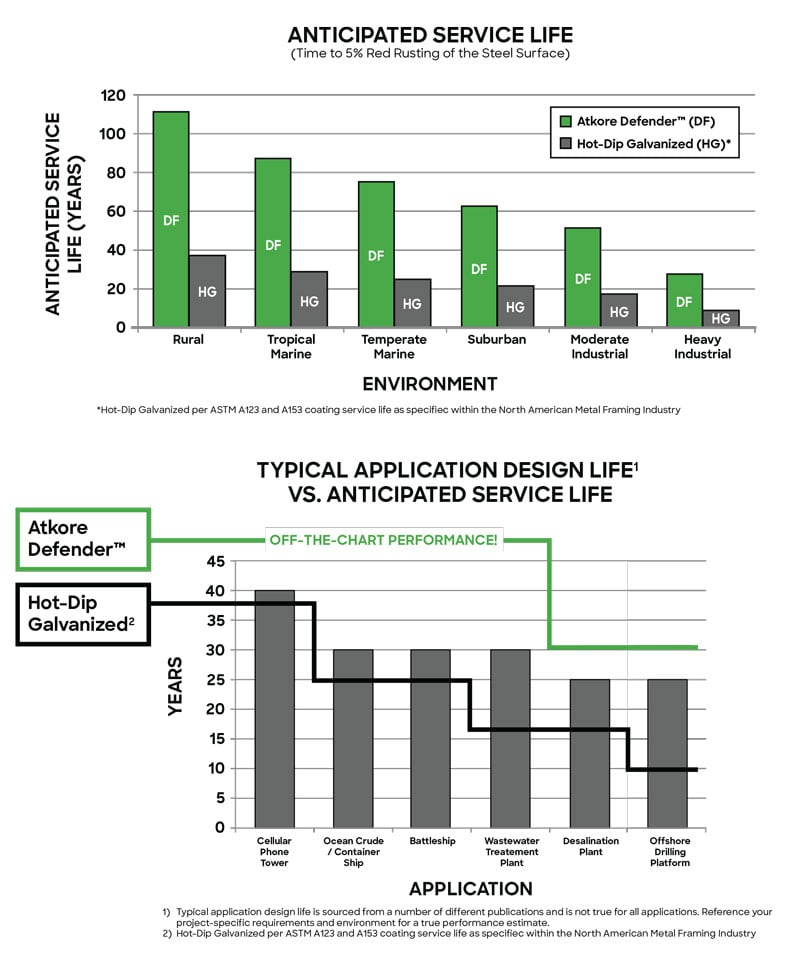

Anticipated Service Life

With over 3 times the corrosion protection of Hot-Dip Galvanized products, the anticipated service life for Atkore Defender vastly outperforms traditional carbon steel framing systems. Atkore Defender will meet the design life of most new applications, eliminating the need to eplace parts over time. See the difference below!

Why Use Unistrut Defender?

- 10 Year Warranty

- 3x the Performance of Hot-Dip Galvanized*

- Significant Cost Savings

- Corrosion-Resistant

- Avoids Need for Costly Stainless Steel Hardware

- Unique Self-Healing Properties

* Based on average ASTM B117 salt spray test (see image)

Although Hot-Dip Galvanized is the most common finish, there are some serious drawbacks when using HDG for outdoor applications. First, Hot-Dip Galvanized steel typically reaches 5% red rust after just around 1000 hours of continuous salt spray exposure based on industry standard testing. As a result, the anticipated service life for galvanized steel in outdoor applications is often less than that of the facility in which it is installed, requiring a complete teardown and reinstallation at some point throughout the life of the building. Over the long term, particular attention must be given to exposed struts and fittings fabricated from galvanized steel, since these components are especially vulnerable to the elements.

For these reasons many engineers and builders instead utilize stainless rather than rely on galvanized. Stainless offers great performance in comparison, but at what price differential? Stainless steel is often two to five times more expensive than hot-dip galvanized steel for a given application.

So, the tradeoff has been whether to have the superior protection of stainless at a higher cost, or lesser protection at a significantly lower cost. Until now, no effective alternatives have been available. Engineers and contractors still want improved protection from corrosion, while maintaining a lower price point than stainless steel. Fortunately, new coatings that have come on the market are making a huge impact on the construction industry and are providing better coating options for strut, fittings, and other members.

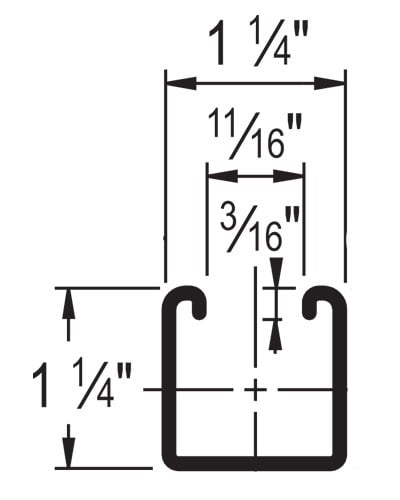

This brochure lists the Unistrut Defender parts, dimensions and applications that are commonly in stock. Many other Unistrut parts can be made by request.

Technical Information

Finishes:

Atkore Defender is a combination of two proprietary material coatings conforming to ASTM standards A1046 and A1059.

Materials:

Channel, Fittings and Pipe Clamps meet the physical requirements of ASTM A1011 SS GR 33.

Technical Notes:

1. Structural performance, including Slip and Pull-Out Loads, meets all Allowable Loads as specified in the Unistrut General Engineering catalog for carbon steels. Please reference the Unistrut General Engineering catalog for this information.

2. To achieve full performance and cost benefits, Atkore Defender must be used as a complete metal framing system. In addition, caution should be taken when putting Atkore Defender in contact with stainless steel materials due to a dissimilar metals condition that may cause galvanic corrosion.

3. Some red staining may be observed over time on Atkore Defender parts in corrosive environments. Red staining is superficial oxidation of the zinc/iron ions at the surface, and not corrosion of the substrate steel. This is noted in ASTM A1059 section 6.3.

4. One of the unique characteristics of Atkore Defender strut channel is that it contains self-healing properties. If the product is cut or scratched in the field, the finish will propagate into those areas eliminating the need for secondary touch-ups.

B117 Salt Spray Test Results

Unistrut Defender Applications

The Atkore Defender premium finish has proven to be ideal for corrosive outdoor environments in many common applications

including:

- Industrial Facilities

- Rooftop Supports

- Transportation

- Railways

- Parking Structures

- Bridges

- Solar Panel Framing

- Walkways

- Platforms

- Railing

- Theme Parks,

- and more

Unique Healing Properties

One unique characteristic of the Unistrut Defender finish is that it contains self-healing properties. If the product is cut or scratched in the field, the finish will propagate into those areas eliminating the need for secondary touch-ups. This gives a sense of confidence that the material will provide lasting defense against corrosion in the field.