Unistrut Finishes

More Information About Unustrut Finishes

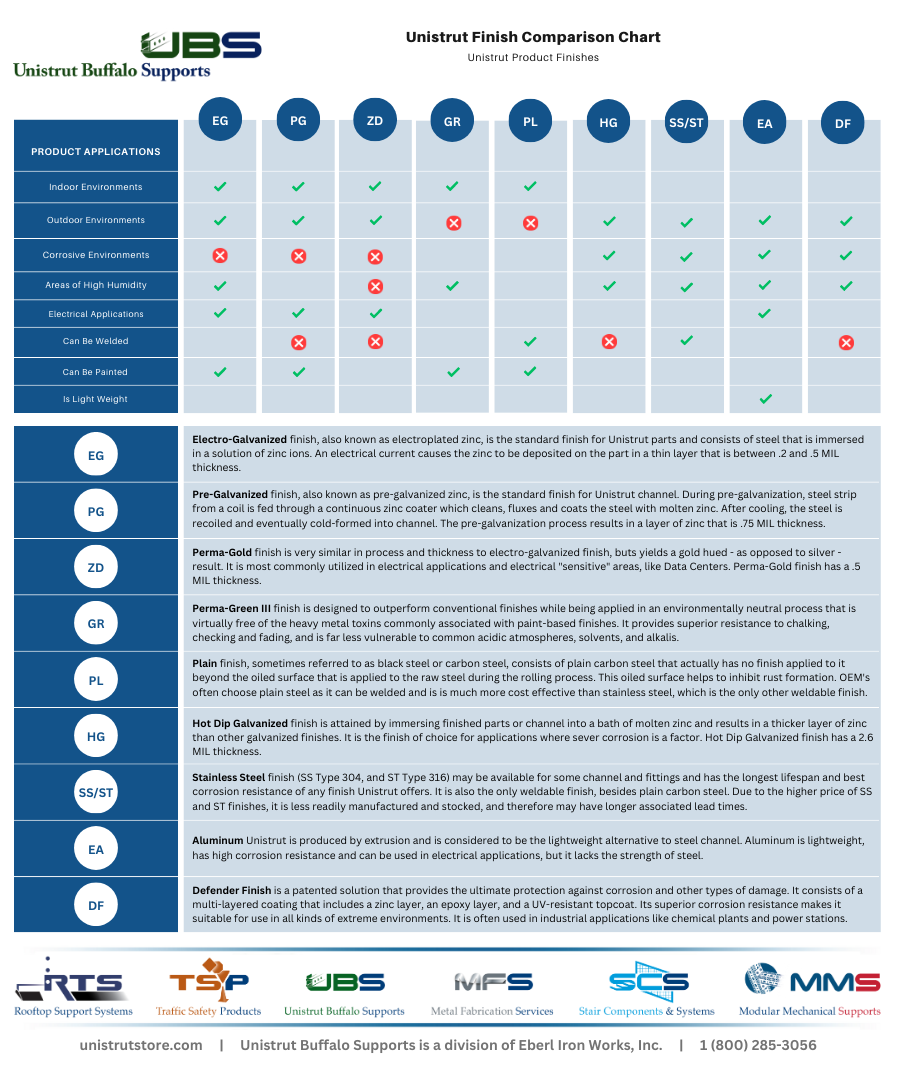

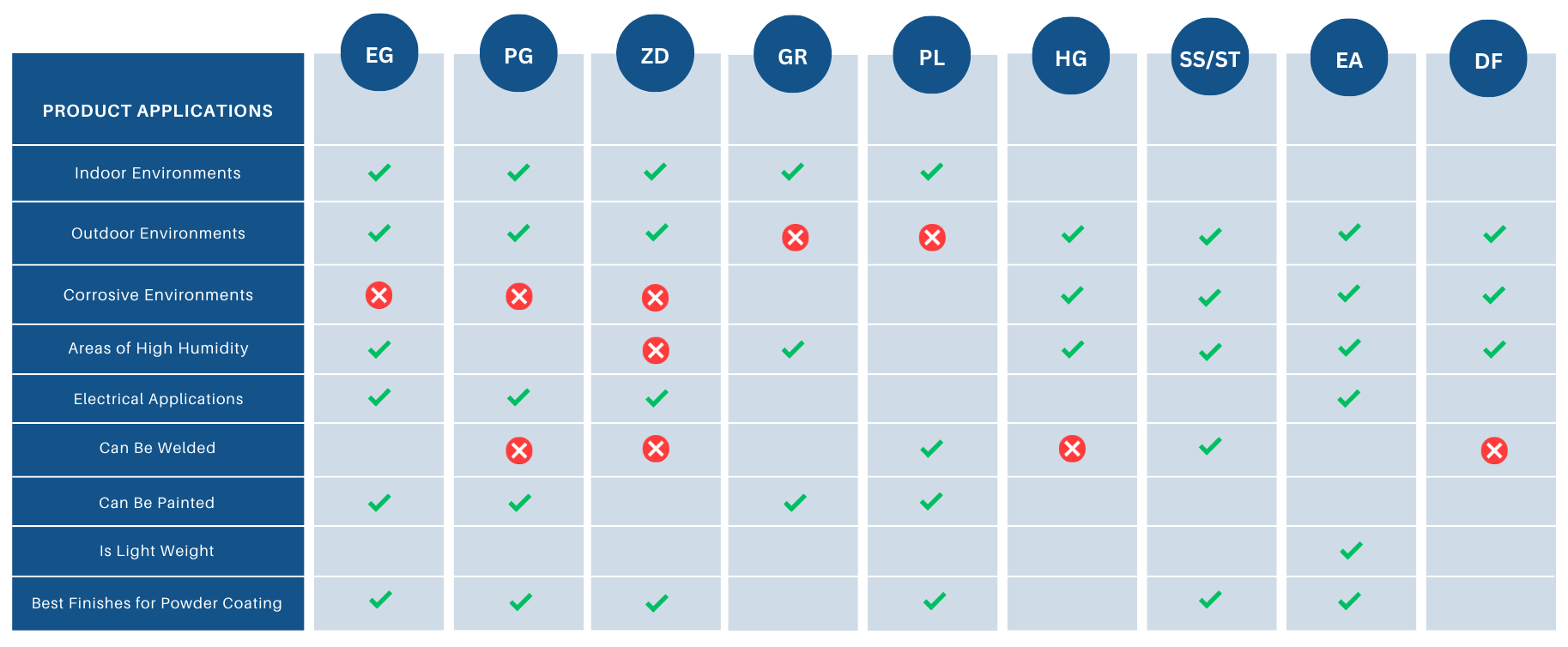

Electro-Galvanized (EG)

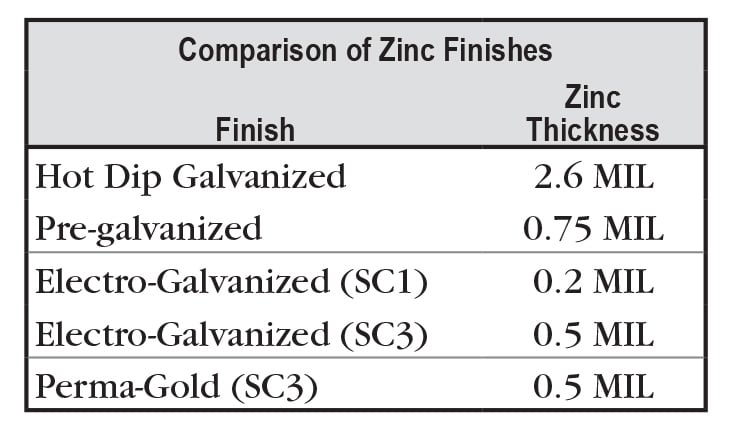

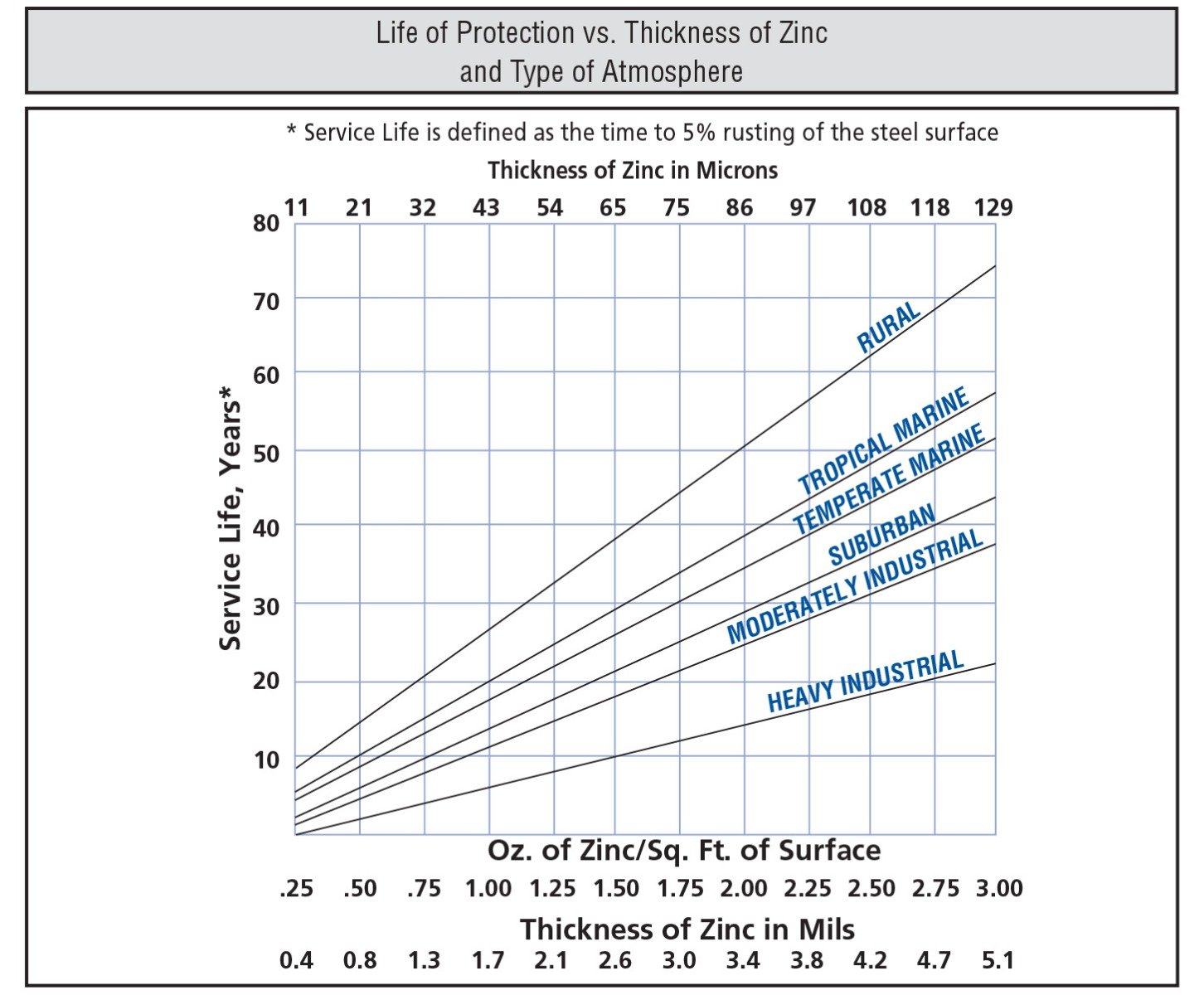

Electro-Galvanized finish, also known as electroplated zinc, is the standard finish for Unistrut parts and consists of steel that is immersed in a solution of zinc ions. An electrical current causes the zinc to be deposited on the part in a thin layer that is between .2 and .5 MIL thickness.

Pre-Galvanized (PG)

Pre-Galvanized finish, also known as pre-galvanized zinc, is the standard finish for Unistrut channel. During pre-galvanization, steel strip from a coil is fed through a continuous zinc coater which cleans, fluxes and coats the steel with molten zinc. After cooling, the steel is recoiled and eventually cold-formed into channel. The pre-galvanization process results in a layer of zinc that is .75 MIL thickness.

Perma-Gold (ZD)

Perma-Gold finish is very similar in process and thickness to electro-galvanized finish, buts yields a gold hued - as opposed to silver - result. It is most commonly utilized in electrical applications and electrical "sensitive" areas, like Data Centers. Perma-Gold finish has a .5 MIL thickness.

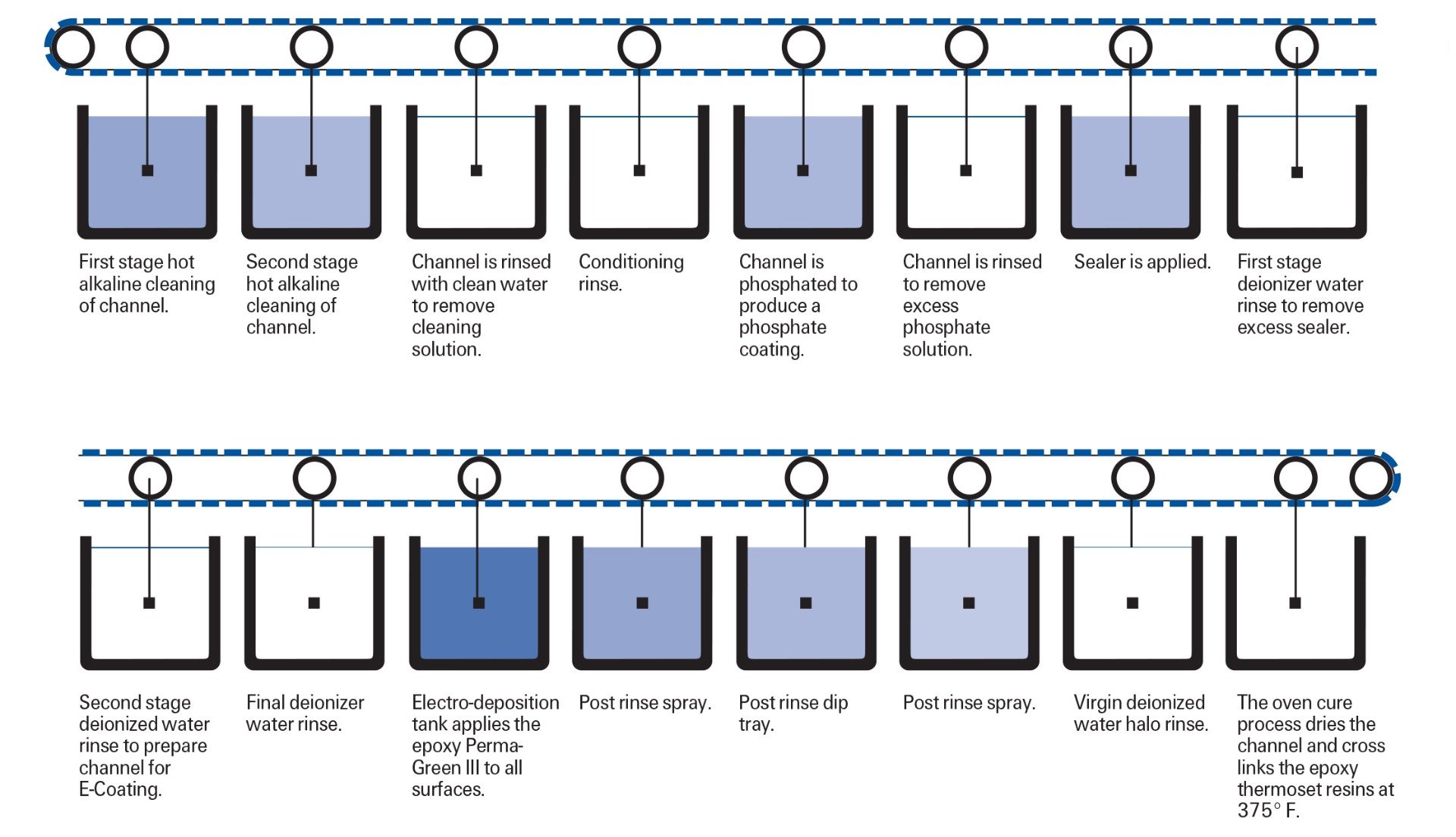

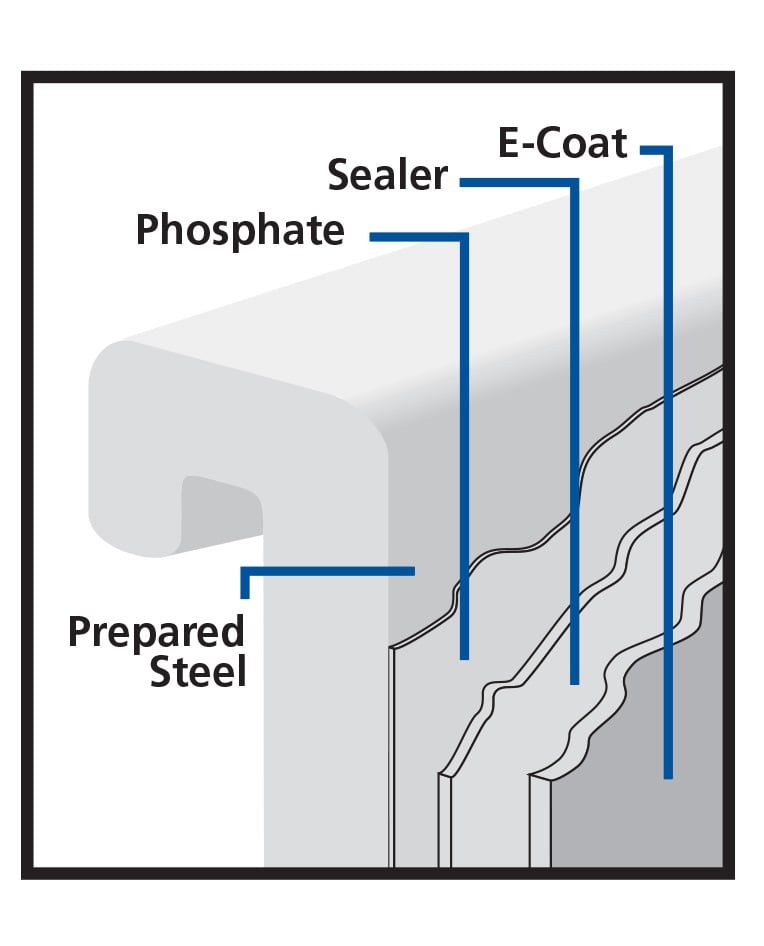

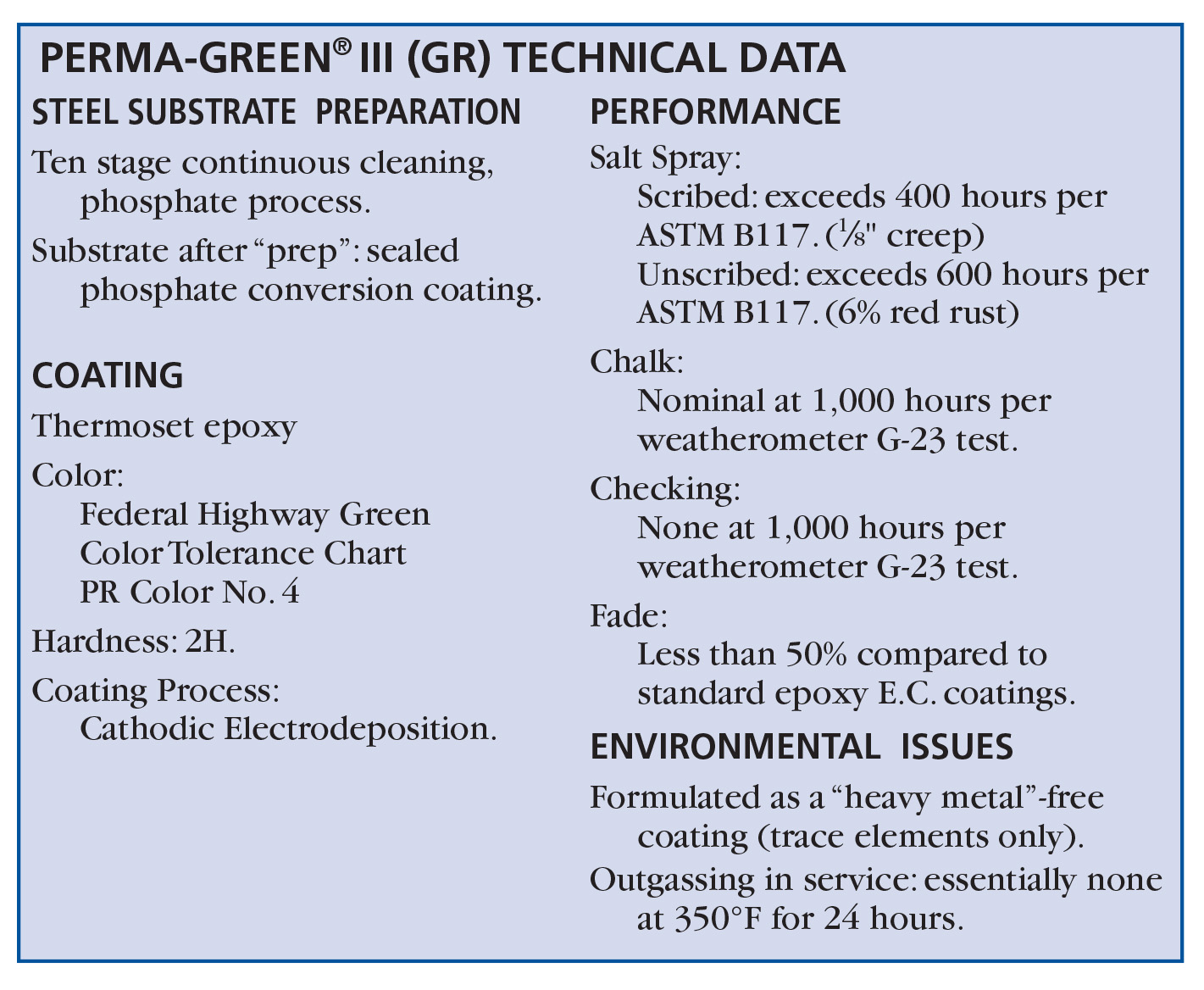

Perma-Green III (GR)

The performance of Unistrut’s Perma-Green III far exceeds that of conventional finishes. And compared to competitive “high-performance” coatings, Perma-Green III provides superior resistance to chalking, checking and fading and is far less vulnerable to common acidic atmospheres, solvents and alkalis. Just as important, Perma-Green III is the result of an environmentally neutral process that virtually eliminates the toxic metals commonly found in competitive paint-based finishes.

Plain Carbon Steel (PL)

Plain finish, sometimes referred to as black steel or carbon steel, consists of plain carbon steel that actually has no finish applied to it beyond the oiled surface that is applied to the raw steel during the rolling process. This oiled surface helps to inhibit rust formation. OEM's often choose plain steel as it can be welded and is is much more cost effective than stainless steel, which is the only other weldable finish.

Hot Dip Galvanized (HG)

Hot Dip Galvanized finish is attained by immersing finished parts or channel into a bath of molten zinc and results in a thicker layer of zinc than other galvanized finishes. It is the finish of choice for applications where sever corrosion is a factor. Hot Dip Galvanized finish has a 2.6 MIL thickness.

Stainless Steel (Type 304: SS, Type 316: ST)

Stainless Steel finish (SS Type 304, and ST Type 316) may be available for some channel and fittings and has the longest lifespan and best corrosion resistance of any finish Unistrut offers. It is also the only weldable finish, besides plain carbon steel. Due to the higher price of SS and ST finishes, it is less readily manufactured and stocked, and therefore may have longer associated lead times.

Aluminum (EA)

Aluminum Unistrut is produced by extrusion and is considered to be the lightweight alternative to steel channel. Aluminum is lightweight, has high corrosion resistance and can be used in electrical applications, but it lacks the strength of steel.

Defender Finish (DF)

Defender Finish is a patented solution that provides the ultimate protection against corrosion and other types of damage. It consists of a multi-layered coating that includes a zinc layer, an epoxy layer, and a UV-resistant topcoat. Its superior corrosion resistance makes it suitable for use in all kinds of extreme environments. It is often used in industrial applications like chemical plants and power stations.