Data Center Construction

Streamlining Data Center Construction with Unistrut Prefabrication

Data centers are the lifeblood of the modern world, housing the critical infrastructure that keeps our businesses and lives running smoothly. But constructing these complex facilities can be a daunting task, with tight deadlines, stringent quality requirements, and a need for precision.

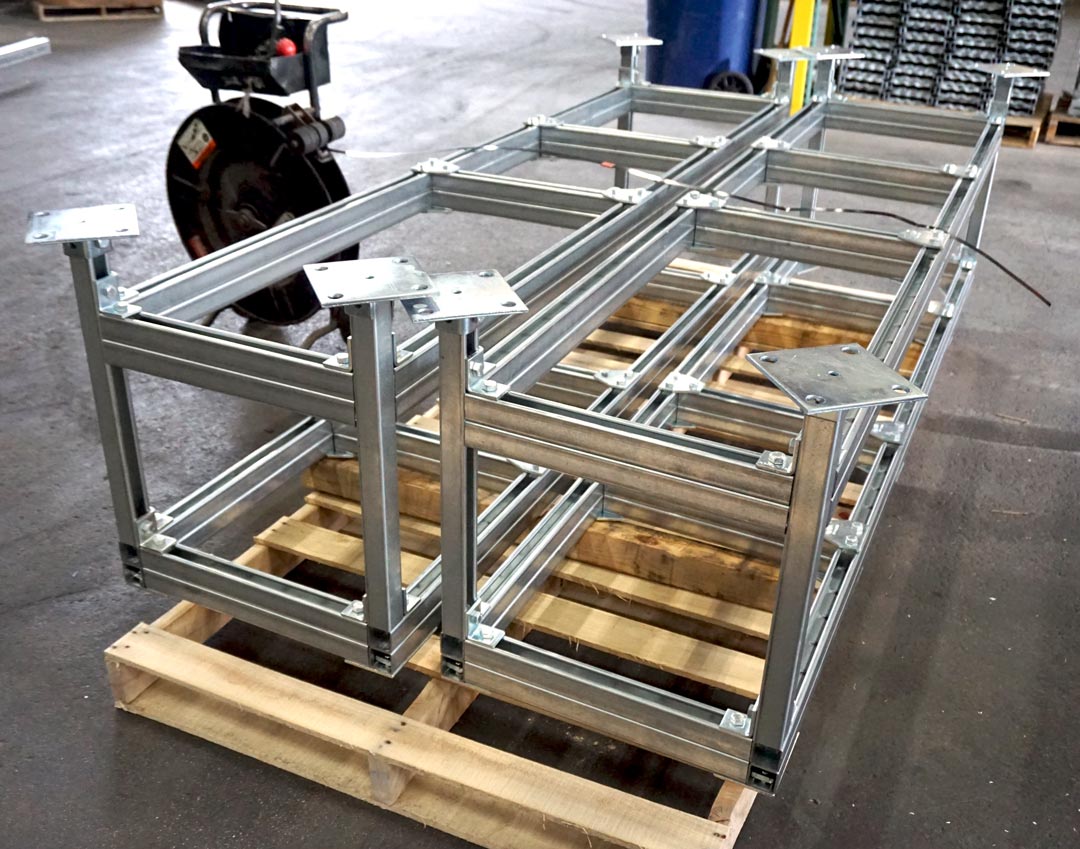

That's where Unistrut Prefabrication comes in. By prefabricating key data center components off-site, you can significantly reduce construction time, lower your data center construction cost, and reduce errors, all while ensuring a high-quality finished product.

What is Unistrut Prefabrication?

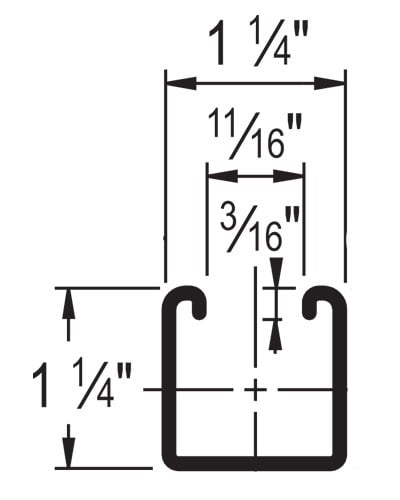

Unistrut is a versatile building system consisting of metal channels, fittings, and accessories. It's widely used in data center construction for a variety of structural support applications, including:

- Overhead Cable Tray Supports

- Modular Racks and Enclosures

- Hot Aisle Containment Systems

- Security Cages

- Seismic Bracing

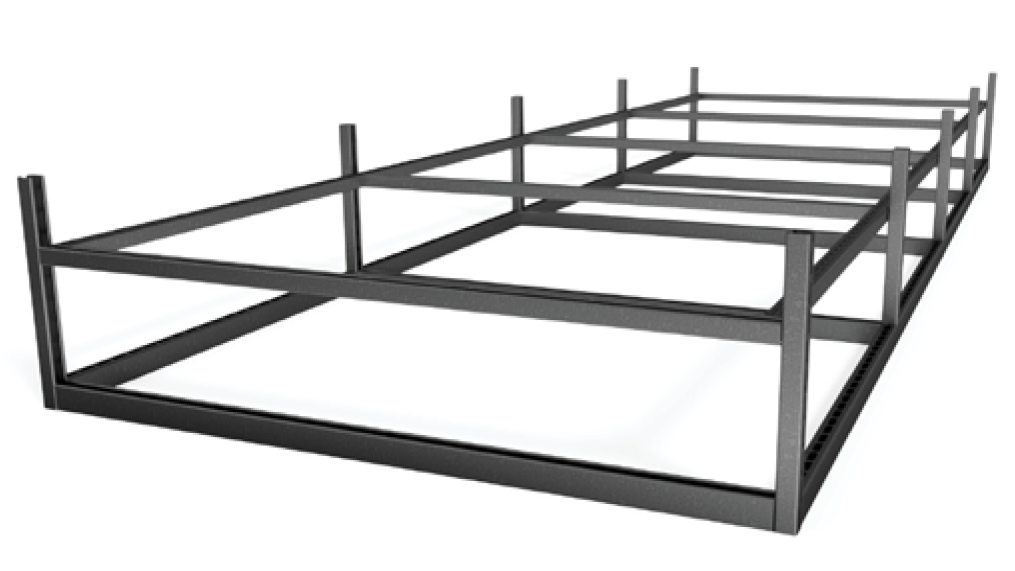

- Ground Mounted Multitrade Rack

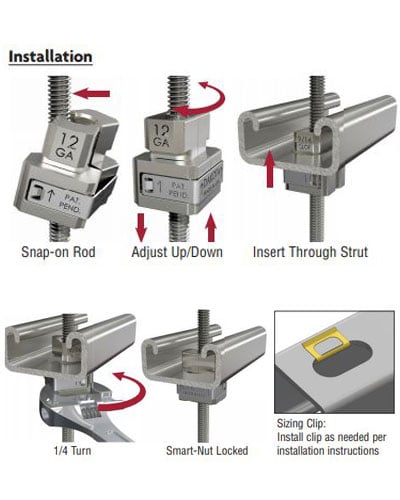

With prefabrication, these components are cut, drilled, and assembled in a controlled off-site environment, according to your specific project requirements. This eliminates the need for on-site cutting, welding, and drilling, which can be time-consuming, error-prone, and require specialized skills.

Benefits of Unistrut Prefabrication for Data Centers

There are many advantages to using Unistrut Prefabrication for your data center project, including:

- Reduced construction time: By prefabricating components off-site, you can significantly reduce the amount of time needed for on-site assembly. This can be critical for projects with tight deadlines.

- Improved quality: Controlled off-site fabrication ensures consistent quality and accuracy, reducing the risk of errors and rework.

- Lower costs: Prefabrication can save you money on labor, materials, and equipment rental.

- Enhanced safety: With less cutting, welding, and drilling on-site, you can create a safer work environment for your crews.

- Increased sustainability: Prefabrication can help reduce waste and energy consumption by using materials more efficiently.

Applications of Unistrut Prefabrication in Data Centers

Unistrut Prefabrication is a powerful tool that can help you streamline the construction of your data center, saving you time, money, and resources. If you're looking for a way to build your data center faster, better, and more efficiently, Unistrut prefabricated mep modules offer the perfect solution.

Unistrut Prefabrication can be used for a wide variety of applications in data centers, including:

- Overhead Cable Tray Supports: Prefabricated cable trays and supports can be quickly and easily installed, ensuring proper cable management and airflow.

- Racks and Enclosures: Prefabricated modular racks and enclosures can be customized to meet your specific needs and arrive ready to install.

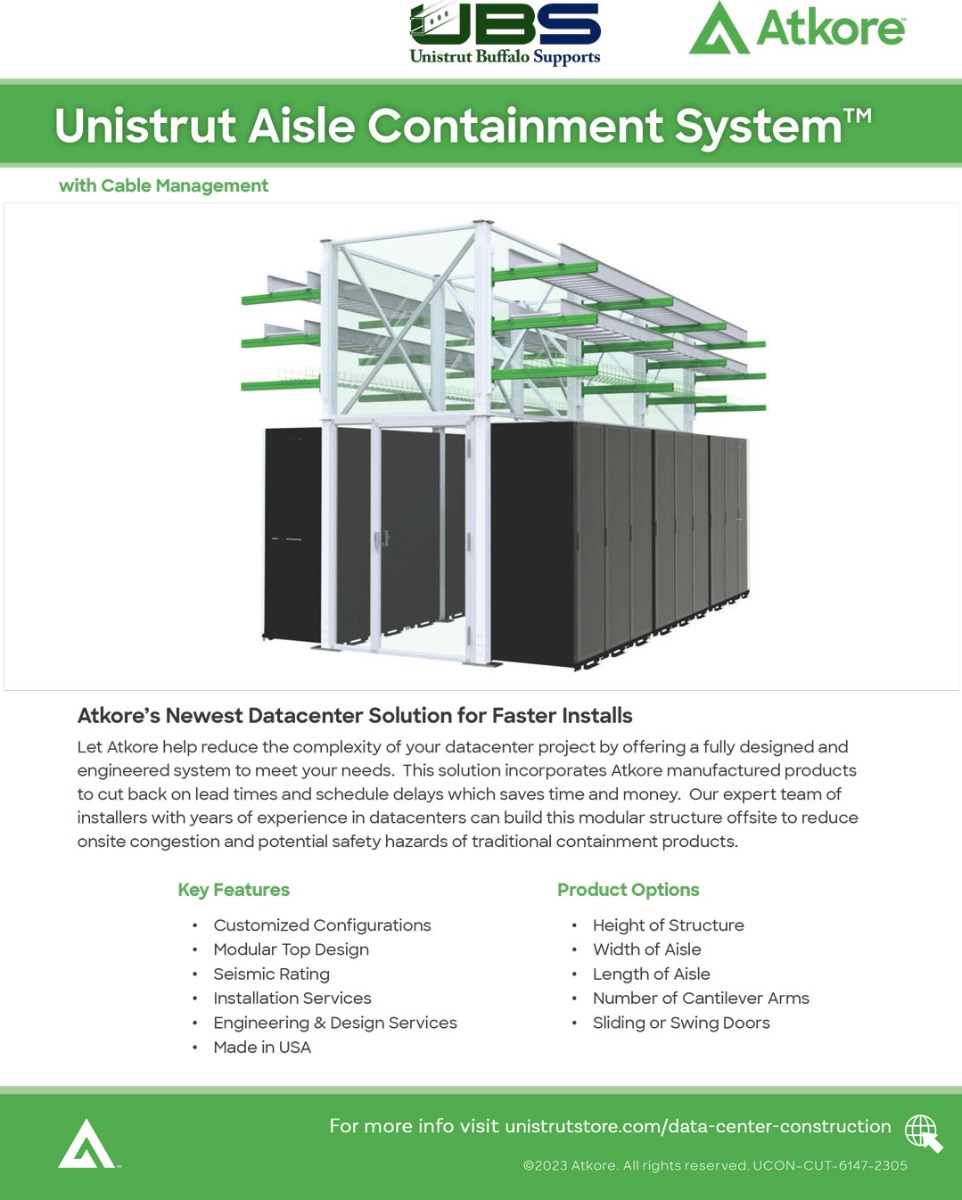

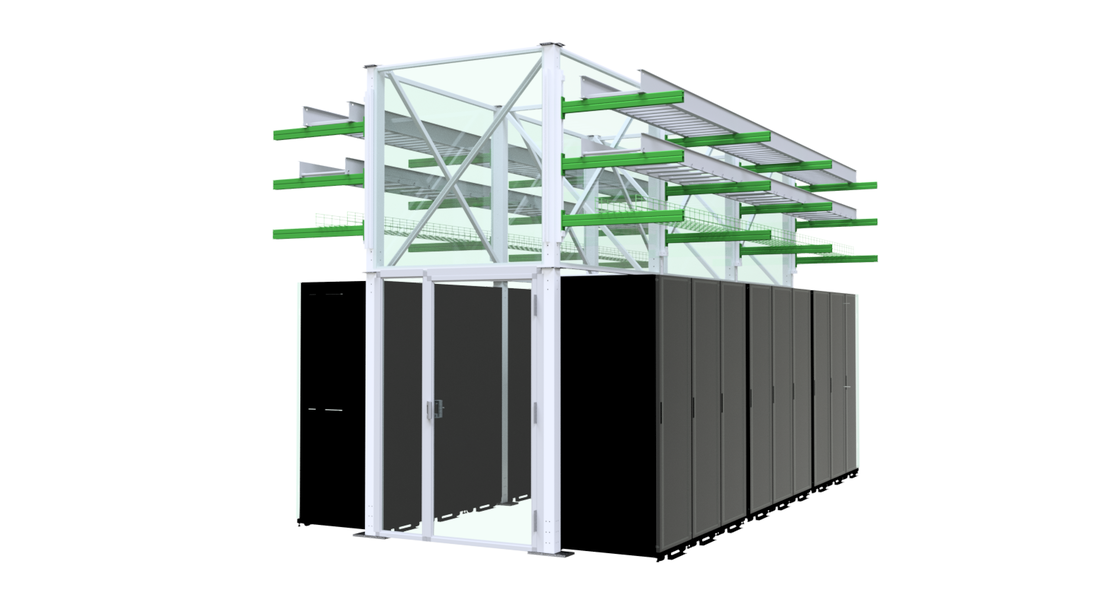

- Hot Aisle Containment Systems: Prefabricated hot aisle containment ceiling grid systems can help improve energy efficiency by preventing hot air from mixing with cool air.

- Security cages: Prefabricated security cages can provide a secure environment for sensitive equipment.

- Seismic bracing: Prefabricated seismic bracing can help protect your data center from damage in the event of an earthquake.

What's the Best Way to Overcome Data Center Construction Challenges?

Partner with Unistrut Buffalo Supports! We are the longest consecutively running Independent Unistrut Contractor in the world, and we know how to support you. When you partner with us, you can expect to benefit from unparalleled product knowledge, expertise and experience. We are committed to providing our customers with the highest quality, most cost effective prefabricated Unistrut sytems.

If you are in the market for a solution that is easier and more cost effective to install than a welded support sytem, with the added benefit of full adjustability in the field, then look no further than Unistrut Prefabrication for your Data Center Construction project.

Hot and Cold Aisle Containment Systems

What is Cold Aisle Containment?

Data Center cold aisle containment improves cooling efficiency by isolating the cold air supply. Cold aisle containment (CAC) is a cooling strategy in data center construction that involves physically enclosing the cold aisles to separate cold air from hot air. The cold aisle is typically the area in front of server racks where cold air from the air conditioning units is directed. Cold aisle containment is commonly used in data centers where precise temperature control and energy efficiency are critical. It is particularly useful in environments with high-density server configurations.

By implementing cold aisle containment, data centers can achieve better cooling performance, enhance energy efficiency, and maintain optimal operating conditions for their equipment.

Unistrut Data Center Construction solutions utilize high quality materials and are design engineered for efficiency. Our system offering designed to provide a complete cold aisle containment system for data center cooling projects. This flexible solution is available for data center hot aisle containment as well, with integrated strut elements to support:

- cable tray

- wire basket

- lighting

- busbar systems

Why Choose Unistrut for your Aisle Containment?

Skilled engineers design our turnkey steel strut channel modular containment and cable management systems to meet your specific requirements. We integrate all aspects of cable management and containment into a single modular design. This makes it easy to create and maintain a safe and efficient data center infrastructure.

Unistrut aisle containment systems can be designed to fit any rack configuration including aisles with varying rack heights, widths, depths, and alignment.

- Designed and engineered to project specification

- Installation drawings and service

- Seismic Category D rating

- Modular design improves install efficiency

- Unparalleled health and safety benefits

- Vertically integrated manufacturing

- Swing and sliding door options

Data Center Prefabrication Components

- Overhead Cable Tray Supports

- Modular Racks and Enclosures

- Hot Aisle Containment Systems

- Security Cages

- Seismic Bracing

- Ground Mounted Multitrade Racks

Learn More About Unistrut Prefabrication

Unistrut Prefabrication isn't just for Data Centers, and it isn't just for Unistrut Metal Framing! Learn more about prefabrication and assembly, including what additional materials are available to use in our prefabrication process, also learn all about our special packaging and labeling services that make installation a breeze!

Head to our Unistrut Prefabrication and Assembly page now!

Unistrut Aisle Containment Literature

Let Atkore help reduce the complexity of your datacenter project by offering a fully designed and engineered system to meet your needs. This solution incorporates Atkore manufactured products to cut back on lead times and schedule delays which saves time and money!