How to Use Unistrut: A Comprehensive Guide for Contractors & OEMs

Unistrut is a versatile metal framing system that was designed to simplify the construction process. This system features a patented, weldless connection that allows for quick and easy assembly. Unistrut has become an industry-standard in commercial and industrial applications due to its flexibility and strength. In this comprehensive guide, contractors and OEMs will learn how to use Unistrut for a variety of purposes.

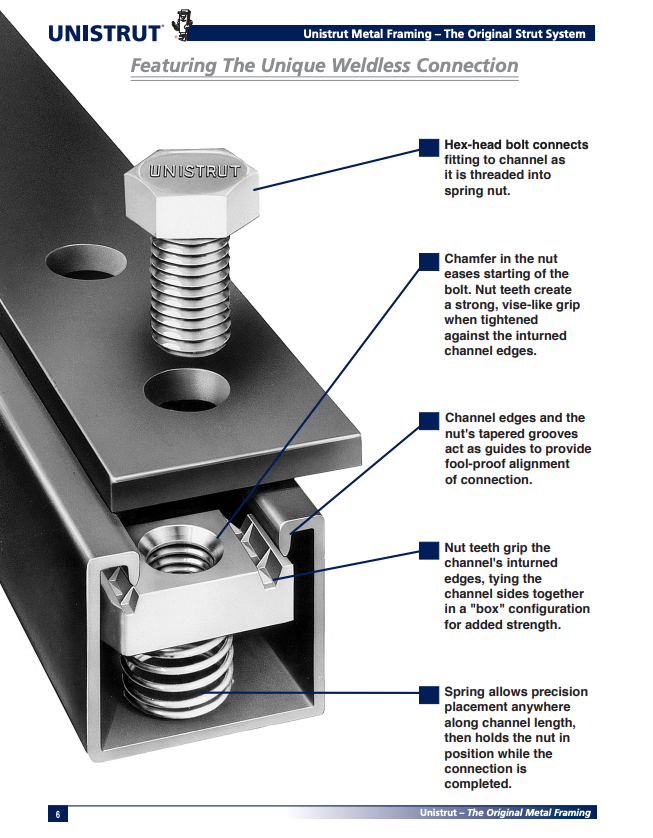

What Makes Unistrut Metal Framing Unique?

Unistrut’s unique weldless connection is what sets it apart from other metal framing systems.

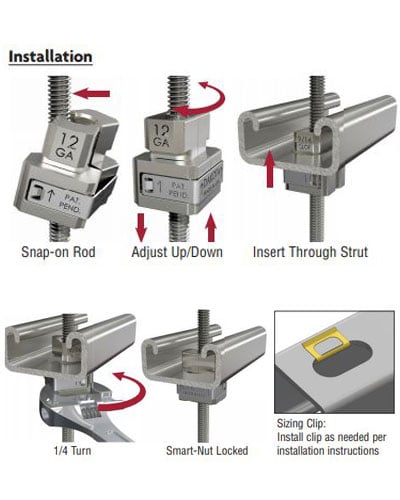

Here’s how it works:

1. The hex-head bolt connects the fitting to the channel as it is threaded into a spring nut.

2. The chamfer in the nut eases the starting of the bolt. The nut teeth create a strong, vice-like grip when tightened against the inturned channel edges.

3. The channel edges and the nut's tapered grooves act as guides to provide a fool-proof alignment of connection.

4. The nut teeth grip the channel's inturned edges, tying the channel sides together in a "box" configuration for added strength.

5. The spring allows precision placement anywhere along channel length, then holds the nut in position while the connection is completed.

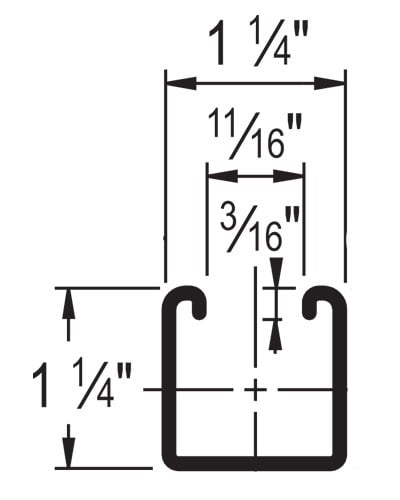

Unistrut is easy to cut, drill and shape with standard tools, saving money and time at the jobsite. Its strength is comparable to welded metal framing, ensuring that the frame remains secure and stable throughout its life cycle. Unistrut also comes in a variety of sizes, channel configurations, and finishes to accommodate any project size or application.

Uses for Unistrut Metal Framing

Medical Equipment Supports:

Unistrut is an ideal choice for supporting medical equipment such as overhead x-rays, CRT monitors, and surgical lights. The system’s unique weldless connection allows for easy installation of the support members without compromising on strength or integrity. Additionally, Unistrut can also be modified to create custom supports for special medical equipment.

See examples of using Unistrut for medical equipment support applications here.

Prefabricated Utility Racks:

Unistrut is an excellent choice for prefabricated utility racks. The system’s weldless connection works great with pre-cut pieces of Unistrut, allowing contractors and OEMs to quickly assemble the rack without worrying about welding. Unistrut is also durable and lightweight, making it an ideal choice for these types of applications.

See examples of using Unistrut for prefabricated utility rack applications here.

Mechanical Rooftop Support Systems:

The weldless connection in Unistrut makes it perfect for creating mechanical rooftop support systems. The system’s design allows for easy installation of the support members, while still providing a strong and secure structure. Additionally, Unistrut is lightweight and corrosion-resistant, which means it will stand up to the elements without issue.

See examples of using Unistrut for rooftop support applications here.

Catwalks & Platforms

Unistrut provides safe walking surfaces at elevation making it a great choice for creating catwalks and mezzanines. Thanks to its weldless connection, this system is easy to assemble yet still offers unbeatable strength and stability.

See examples of using Unistrut for catwalk and platform applications here.