Aickinstrut vs Unistrut Fiberglass Strut

When it comes to choosing the right fiberglass strut for your project, Atkore manufactures the best on the market. The benefits of Atkore’s fiberglass strut are undeniable: corrosion-resistant, lightweight, and versatile. The applications are diverse, ranging from Waste Water Treatment and Refineries to Theme Parks and Underground Vaults. As you’re planning your project, it’s crucial to assess which fiberglass channel profile is going to be best for what you’re trying to accomplish. The goal of this blog post is to give you the pros and cons of Atkore’s two different channel profiles: Aickenstrut Profile and Standard Profile.

But first, here are some common applications in which fiberglass strut is useful.

What Is Fiberglass Strut Used For?

The key properties of fiberglass strut, including corrosion resistance and lightweight design, make it suitable for various industries and projects. Here are some common uses of fiberglass strut:

Waste Water Treatment: Fiberglass strut is employed in the construction of support structures for equipment and piping in wastewater treatment facilities due to its resistance to corrosion in harsh environments.

Refineries: In refineries, where exposure to corrosive substances is common, fiberglass strut provides a durable and corrosion-resistant solution for supporting pipes, conduits, and equipment.

Chemical Plants: The corrosion-resistant nature of fiberglass makes it an ideal choice for supporting structures in chemical plants, ensuring longevity and reliability in corrosive chemical environments.

Marinas: Fiberglass strut is used in marinas for constructing sturdy and corrosion-resistant frameworks for docks, piers, and other marine infrastructure.

Pulp and Paper: The corrosion resistance of fiberglass makes it suitable for use in the pulp and paper industry, where exposure to chemicals and moisture is prevalent.

Desalination Facilities: Fiberglass strut is employed in desalination facilities for supporting various components due to its resistance to corrosion in saline environments.

Theme Parks and Aquariums: The lightweight and corrosion-resistant properties of fiberglass strut make it an excellent choice for constructing support structures in theme parks and aquariums, where durability and aesthetic considerations are important.

Underground Vaults: Fiberglass strut is utilized in the construction of underground vaults, providing structural support in environments where traditional materials may corrode or degrade.

Building Storage Racks: Fiberglass strut is used in the creation of storage racks in buildings, warehouses, and industrial settings, offering a durable and corrosion-resistant alternative.

Pipe Supports: Whether in industrial settings or building infrastructure, fiberglass strut is employed for supporting pipes and conduits, providing a reliable and corrosion-resistant solution.

Solar Supports: In solar energy installations, fiberglass strut is used to create robust support structures for solar panels, offering a corrosion-resistant and durable solution for outdoor environments.

Tank and Equipment Supports: Fiberglass strut is employed for supporting tanks and various equipment in industries where corrosion resistance is critical for long-term performance.

Fiberglass strut finds applications in diverse industries where corrosion resistance, durability, and lightweight design are crucial considerations for support structures and frameworks.

Aickinstrut Vs. Standard Fiberglass Unistrut: Weighing the Options

There are two primary channel profiles when it comes to fiberglass strut: Aickinstrut and Standard, also known as Unistrut SST. Both of these channel profiles are great options when fiberglass solutions are needed, but what are the distinguishing features of each one? Read on to find out.

Aickinstrut: Precision in Design

The Aickinstrut profile distinguishes itself with a pointed flange design that seamlessly interlocks with Aickinstrut fittings. Alos, it is available in three different sizes, for light duty, medium duty, and heavy duty applications.

“Aickinstrut® Fiberglass Strut is the most widely used and accepted nonmetallic strut support system in the world because it is the most complete quality line of nonmetallic accessories, fasteners, hangers, pipe clamps and channels available.” - Atkore Product Guide

What makes Aickinstrut a practical choice is its ease of customization. It can be effortlessly cut to size with tools as basic as a handsaw, ensuring you achieve the exact fit your project demands.

Unistrut SST: Versatility and Compatibility

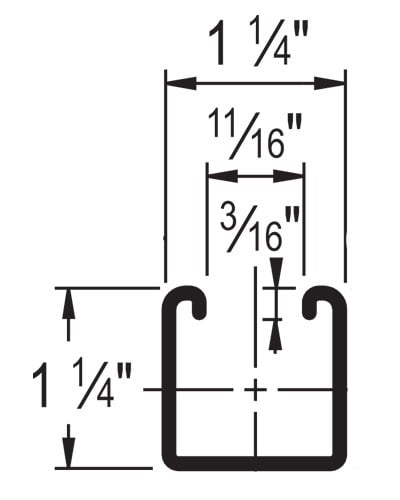

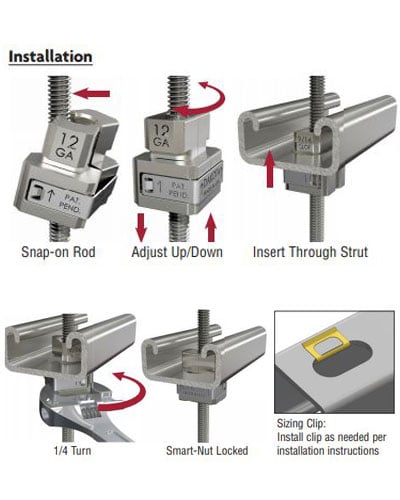

On the other hand, the Unistrut SST profile mirrors the standard metal 1-⅝” Unistrut channel, offering compatibility with standard Unistrut fittings. This compatibility expands your options, allowing the use of a broader range of fittings than what is available with fiberglass fittings. SST fiberglass components seamlessly integrate into existing or new metal Unistrut solutions, offering flexibility in design.

Like Aickinstrut, Unistrut SST can be cut to size with simple tools, providing a hassle-free solution for achieving precise fits. Whether you're adjusting or drilling on-site, Unistrut SST ensures a custom solution aligned with your project's specifications.

Compatibility with Metal Unistrut Channel: A Decisive Factor

One crucial distinction surfaces when considering your options. Whereas Aickinstrut has the most complete line of fiberglass parts available, Unistrut SST is more compatible with its metal counterparts. Unistrut SST stands out for its compatibility with the complete line of metal Unistrut channel, accessories, fasteners, hangers, pipe clamps, and more.

If you find yourself facing a challenge that demands a fiberglass solution, we invite you to contact us at Unistrut Buffalo Supports. Our team is ready to provide the expertise and support needed to ensure your project's success.