Fabrication Services for the Construction & OEM Industries

Our team of experts provide Unistrut Fabrication Services

No matter the job size or the complexity of the project, our team of project managers, estimators and shop employees are able to provide you with the turnkey, component based fabrication services you need. We take your concepts and requirements and use genuine Unistrut Metal Framing, Telespar Posts, Metal Safety Grating, and more to build a custom Unistrut Support System that is right for you. Not only do these fabrication services simplify installation, but they also reduce costs by decreasing man hours and eliminate waste and re-works.

No matter the job size or the complexity of the project, our team of project managers, estimators and shop employees are able to provide you with the turnkey, component based fabrication services you need. We take your concepts and requirements and use genuine Unistrut Metal Framing, Telespar Posts, Metal Safety Grating, and more to build a custom Unistrut Support System that is right for you. Not only do these fabrication services simplify installation, but they also reduce costs by decreasing man hours and eliminate waste and re-works.

What Fabrication Services Are Offered?

We make sure all of your needs are met by offering a wide range of fabrication services. These services include:

Design and Engineering: With over 200 years of collective product knowledge, our design department will help create the right turnkey support solution for your project. Engineer stamped drawings are available.

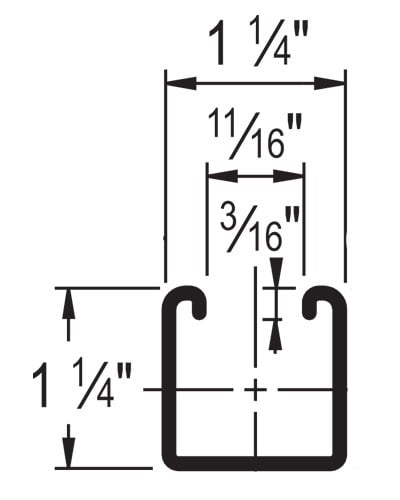

Cut to Length Channel, Tubing and Grating: Our machine operators will saw Unistrut Channel, Telespar Perforated Tubing and Safety Grating to required lengths. Saw cut material ends are cleaned and de-burred, and lengths are packaged for ease of customer use. Piece and pallet marketing is available upon request.

Cut to Length Channel, Tubing and Grating: Our machine operators will saw Unistrut Channel, Telespar Perforated Tubing and Safety Grating to required lengths. Saw cut material ends are cleaned and de-burred, and lengths are packaged for ease of customer use. Piece and pallet marketing is available upon request.

Kitting: Shop employees pre-package channel, fittings and hardware into easy access kits, for ready use by our customers. Piece and pallet marking are available upon request.

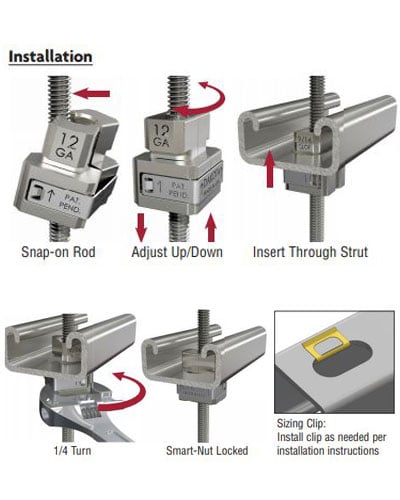

Assembly: Turnkey, pre-cut and assembled Unistrut channel, fittings, hardware, and grating save customers time. With little to no field or production assembly, our customers find that their time savings add up quickly. Turnkey kits are packaged and marked per buyers requirements.

Custom Welding: Shop employees provide custom welding services on Unistrut Framing, Telespar Tubing and Safety Grating. Our highly skilled welders are practiced in many different methods of welding. For more information, contact our estimating department.

Custom Welding: Shop employees provide custom welding services on Unistrut Framing, Telespar Tubing and Safety Grating. Our highly skilled welders are practiced in many different methods of welding. For more information, contact our estimating department.

Hole Punching: Custom hole punching and drilling of channel and tubing is available.

Channel Rolling: Unistrut channel can be rolled in a radius. Our estimating team can help you with your next project.

Plasma and Laser Cutting: If you require special shapes or marking burned into tubing or channel, we can help to accomplish this. We can also fabricate custom parts.

Shearing and Forming: Our fabrication department can incorporate sheet, plate and light structural steel into your design. The collaboration of these three offerings allows us to provide more solutions for our customers.

Hot Dip Galvanized: Batch process A123 galvanizing is available for most metal framing products.

Custom Powder Coating: Our Unistrut division provides powder coating options in a large variety of custom colors.

Custom Powder Coating: Our Unistrut division provides powder coating options in a large variety of custom colors.

Installation: Our design team can provide installation of Unistrut Metal Framing Support projects. Examples of projects we have worked on include Unistrut Medical Supports, Unistrut Ceiling Grids, Unistrut Roof Walks, Unistrut Catwalks and more.

Logistics: Kitted orders are delivered to you or shipped blind to your customers, which allows you to take advantage of our competitive field rates.

Fabrication Services Can Be Used For A Variety Of Applications

Our pre-fabricated supports are commonly used on the following applications:

- Pipe Supports

- Conduit and Cable Tray Supports

- Equipment Stands

- Duct Trapeze Supports

- Battery Racks

- Rooftop Pipe, Duct and Cable Tray Supports

- Catwalk Systems

- Rooftop Walkway Systems

- Equipment Racks

- Crossover Stair Systems

- Unistrut Medical Supports

- Unistrut Ceiling Grids

- Pre-Fabricated Trapeze Hangers

- Casework Pipe Chase Frames

If you have a custom Unistrut support requirement, Contact Unistrut Buffalo Supports design team today to discuss your needs!